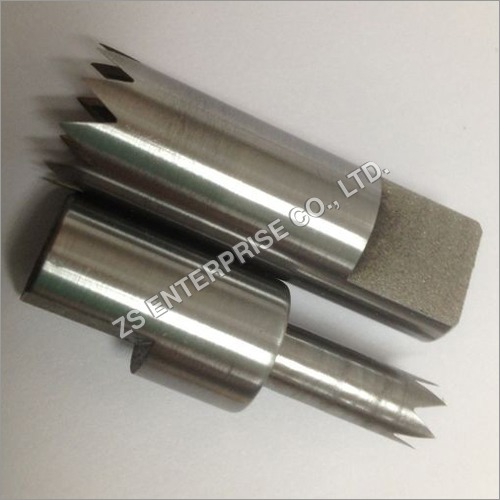

Custom serrated teeth Punch

30 USD ($)/Piece

Product Details:

- Power Rating As per mechanical setup

- Machine Type Metal Forming Tool

- Drive Manual/Mechanical

- Lubricating System Manual

- Cooling System None (Air Cooled / On Demand)

- Accuracy 0.02 mm

- Operating Temperature Up to 150C

- Click to View more

X

Custom serrated teeth Punch Price And Quantity

- 10 Piece

- 30 USD ($)/Piece

Custom serrated teeth Punch Product Specifications

- 500-1000 pcs/month

- Wear-resistant, High Strength, Anti-corrosive, Customizable teeth size and pattern

- Mechanical

- Up to 150C

- CNC Precision Machining

- N/A (Manual/Mechanical)

- Custom as per client requirements

- 0.02 mm

- None (Air Cooled / On Demand)

- Industrial Punching, Metal Sheet Forming, Die Cutting

- Manual

- Serrated Teeth Punch

- Manual / Semi-Automatic

- As per mechanical setup

- Manual/Mechanical

- Metal Forming Tool

- Standard Mechanical

- Customized as per drawing

- Depend on Punch Size

- Low

- Polished / Coated (Anti-Rust)

- 5-15 kg (Depending on size)

- CSTP-01

- Solid Tool Steel

- Natural Metallic Grey

Custom serrated teeth Punch Trade Information

- 1000 Piece Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

Our quality Custom Toothed Punch is acustomdesigned part to fit in the core seating die. This is mainly manufactured as an internal punch to secure the edges in punching. Our product embraces features like easy fitment, elevated durability, and strong design for its untainted use for many decades. With our supreme manufacturing of our Custom Toothed Punch, we are capable of providing both standard and custom sizes of precision toothed punch according to need and use in the application.

Engineered for Precision and Durability

Our custom serrated teeth punches are meticulously crafted using high-speed steel, alloy steel, or tool steel to deliver superior strength, longevity, and optimal sharpness for industrial needs. Finished with precision grinding and polishing, every punch meets strict tolerance requirements, making them an indispensable component in high-precision punching and forming operations.

Tailored Solutions for Diverse Industries

Designed to cater to automotive, metalworking, sheet metal, and tool-and-die sectors, these punches feature custom serrated profiles as per clients drawings or specifications. They can be mounted in various press tools or dies, ensuring seamless integration and reliable operation across a multitude of industrial environments.

Customizable for Unique Requirements

Benefit from a fully customizable manufacturing processwhether its unique tooth designs, specialized finishes, or specific dimensions. Production capacity ranges from 500 to 1000 pieces per month, and with flexible order quantities, we serve distributors, exporters, manufacturers, and suppliers both locally and internationally.

FAQs of Custom serrated teeth Punch:

Q: How are the custom serrated teeth punches manufactured to meet precise specifications?

A: Each punch is produced using CNC precision machining, adhering strictly to your provided drawings or specifications. The materialshigh-speed steel, alloy steel, or tool steelare heat-treated to achieve a hardness of 58-62 HRC, then precision ground and polished to ensure sharp, long-lasting serrated edges with tolerances maintained up to 0.01 mm.Q: What applications are these serrated teeth punches most suitable for?

A: These punches are ideal for industrial punching, metal sheet forming, die cutting, and machine tools used in automotive, metal working, sheet metal, and tool-and-die manufacturing industries. Their durable construction and customizable serrated profiles make them perfect for demanding production environments.Q: When should I choose a custom serrated tooth profile over standard profiles?

A: Custom serrated profiles are recommended when your application requires unique edge geometry, specific cutting performance, or tailored fit that standard punches cannot provide. This ensures precise material processing, better tool longevity, and optimal results for specialized industrial tasks.Q: Where and how are these punches installed?

A: Custom serrated punches are designed to be mounted directly in press tools or dies that are part of your mechanical or manually operated setups. They are compatible with a variety of press tool systems, making installation straightforward with standard mechanical connections.Q: What advantages do these punches offer in terms of durability and maintenance?

A: Engineered to be wear-resistant, high-strength, and anti-corrosive, the punches offer extended tool life and reduced downtime. The polished and coated surface treatments provide additional resistance to rust and abrasion, simplifying maintenance and ensuring consistent performance even under heavy usage.Q: How does the customization process work for specific designs and requirements?

A: Clients can submit their drawings or technical specifications, including desired tooth profiles, dimensions, finish, and required pressure ratings. Our team evaluates and confirms the feasibility, then manufactures the punches to match your exact parameters, ensuring a perfect fit for your operational needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Toothed Punching Machine' category

|

ZS ENTERPRISE CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |