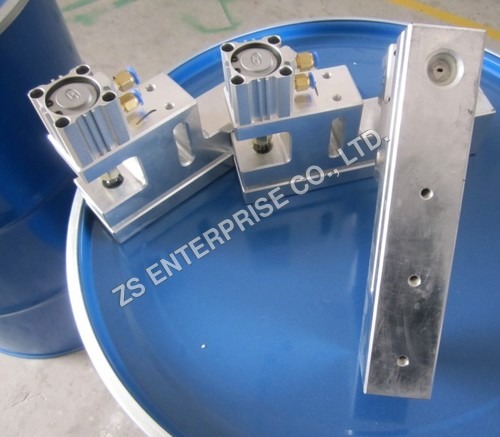

Pneumatic V Notch Punch Machine

120.00 - 300.00 USD ($)/Piece

Product Details:

- Frame Type Heavy Duty Steel Frame

- Lubricating System Manual Lubrication (if required)

- Model No V-NOTCH-01

- Production Capacity 200-400 Pieces per Hour

- Operating Temperature 5C 45C

- Power Rating Pneumatic System Based

- Control System Manual Lever / Pneumatic Cylinder

- Click to View more

X

Pneumatic V Notch Punch Machine Price And Quantity

- 120.00 - 300.00 USD ($)/Piece

- 1 Piece

Pneumatic V Notch Punch Machine Product Specifications

- Pneumatic System Based

- Manual Lever / Pneumatic Cylinder

- 5C 45C

- 200-400 Pieces per Hour

- Approx. 90 kg

- PVC / uPVC / Aluminum Profile

- 0.5-0.7 MPa

- Notching (V-cutting) of plastic profiles, upvc, aluminum, or similar materials

- V Notch Punch Machine

- Heavy Duty Steel Frame

- Not Required (Pneumatic Driven)

- Manual Lubrication (if required)

- Pneumatic

- V-NOTCH-01

- Air Cooled

- <80 dB

- Powder Coated / Painted

- Easy to operate, robust construction, low maintenance, precise notching

- Approx. 650 x 350 x 1200 mm

- Pneumatic Automation

- Manual / Semi-Automatic

- Blue & Black

- Pneumatic Drive

- Notch Punching Machine

- 0.2 mm

Pneumatic V Notch Punch Machine Trade Information

- 1000 Piece Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

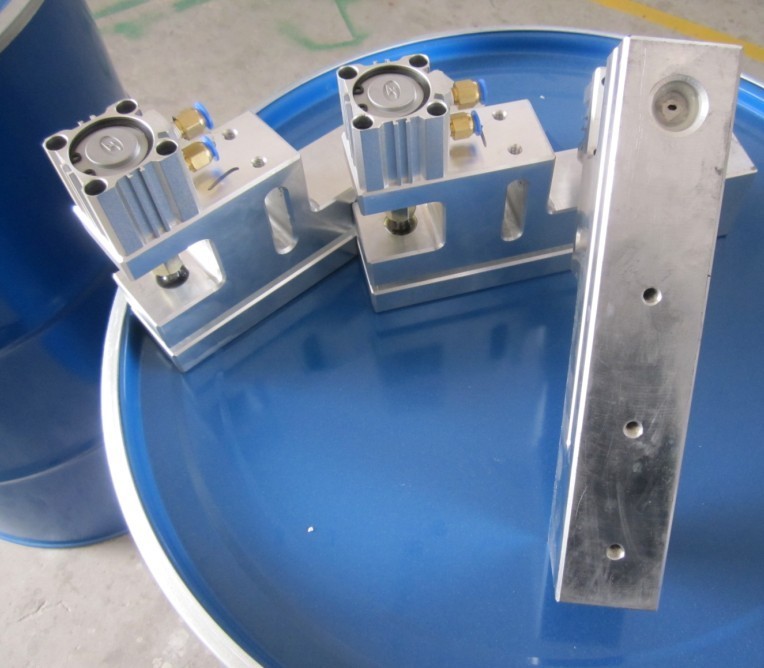

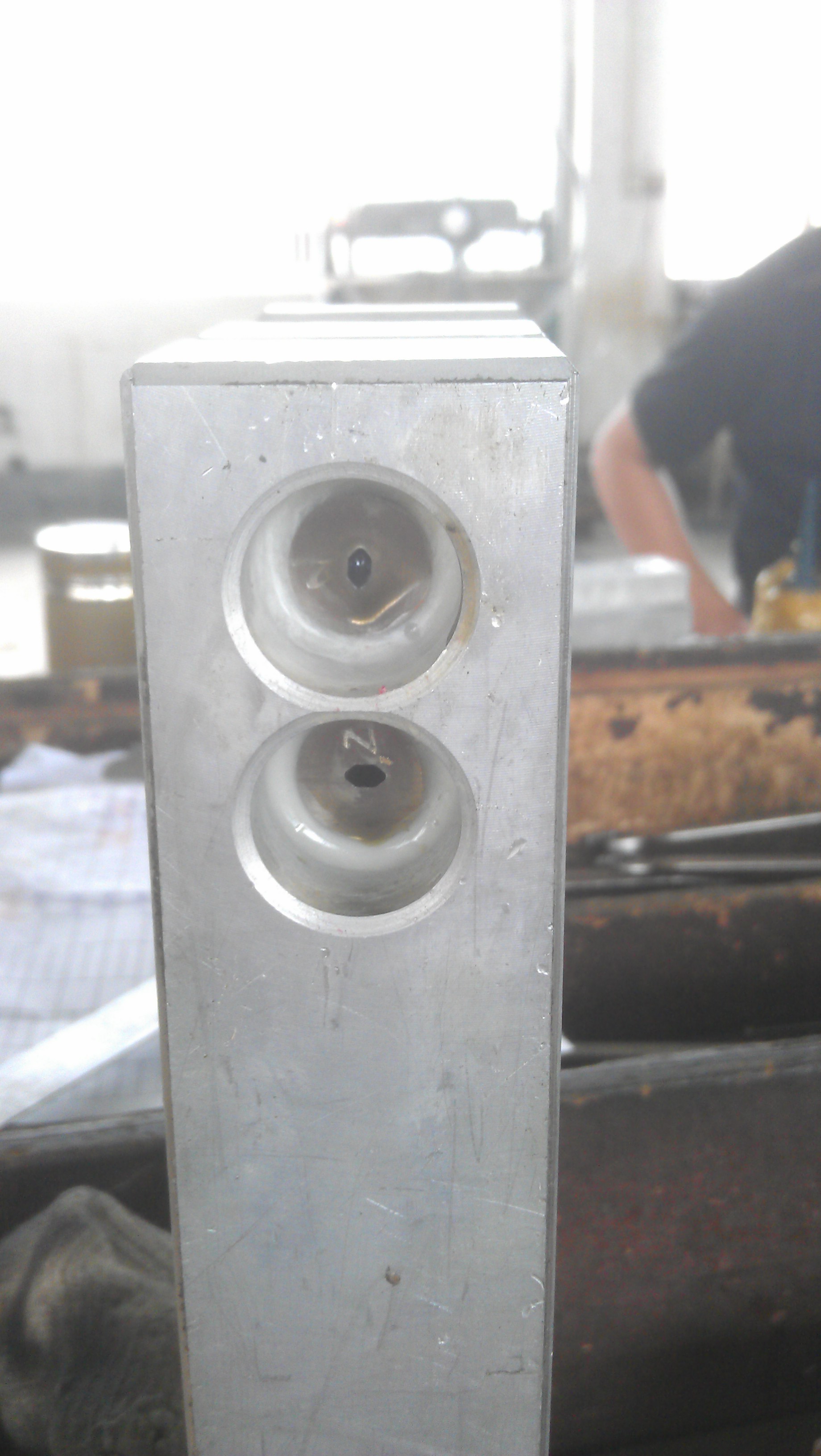

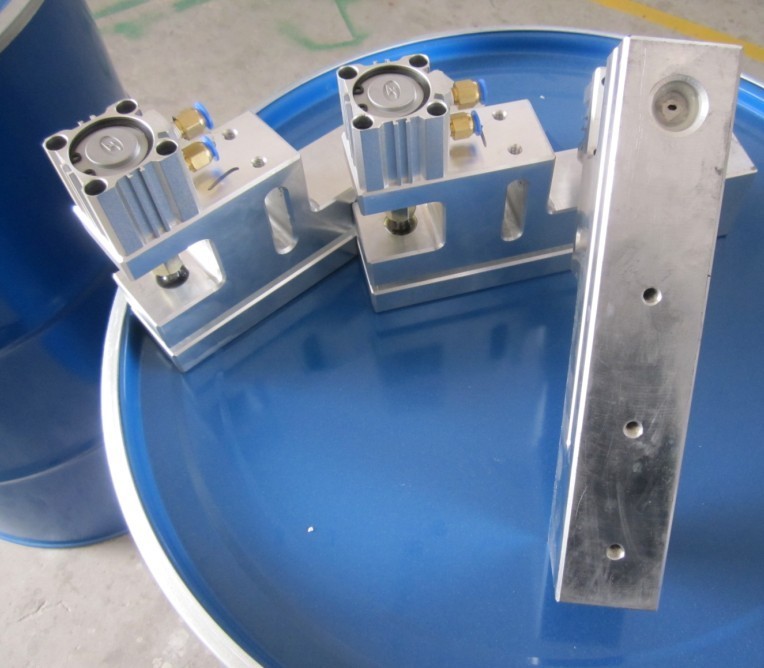

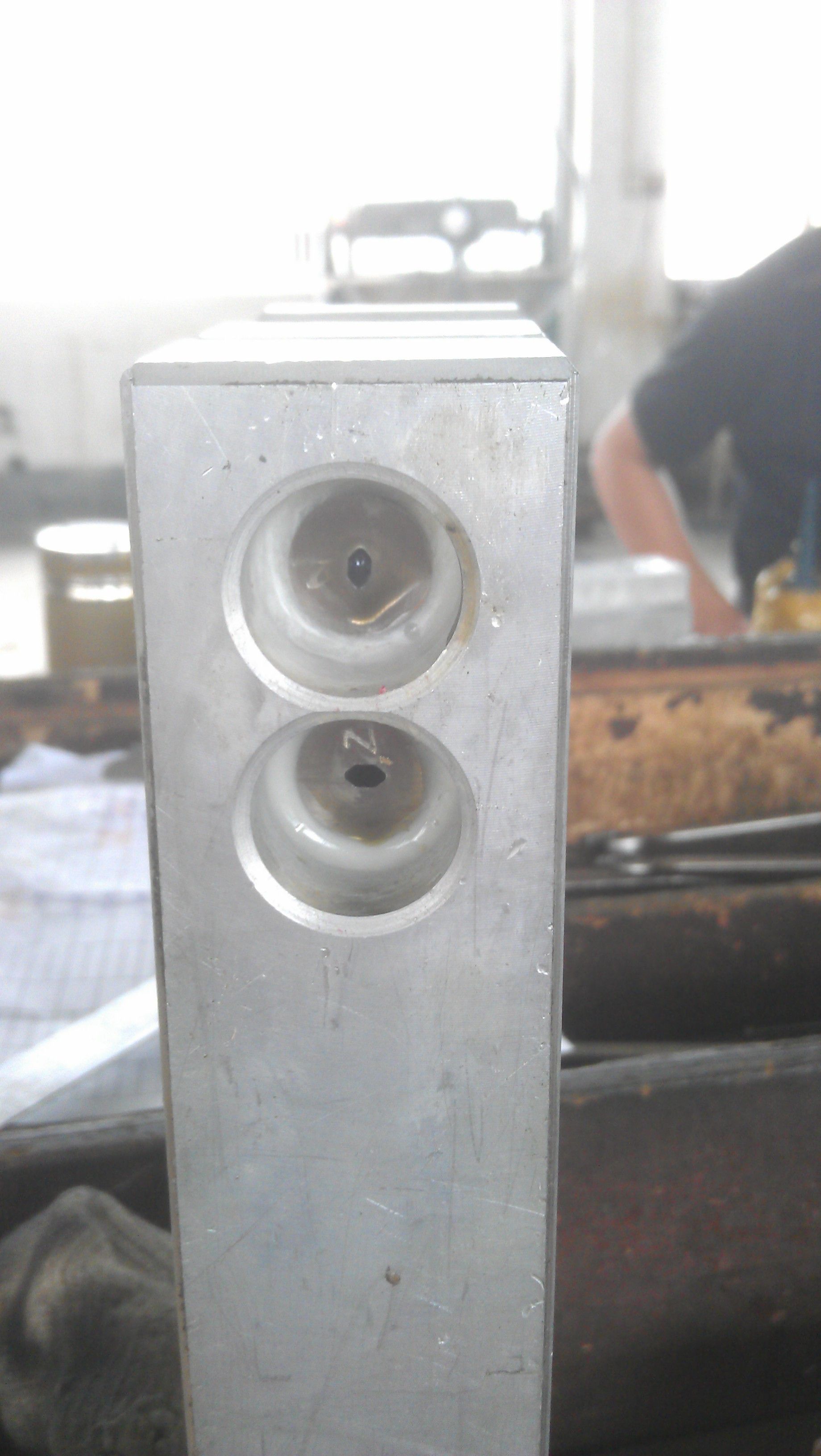

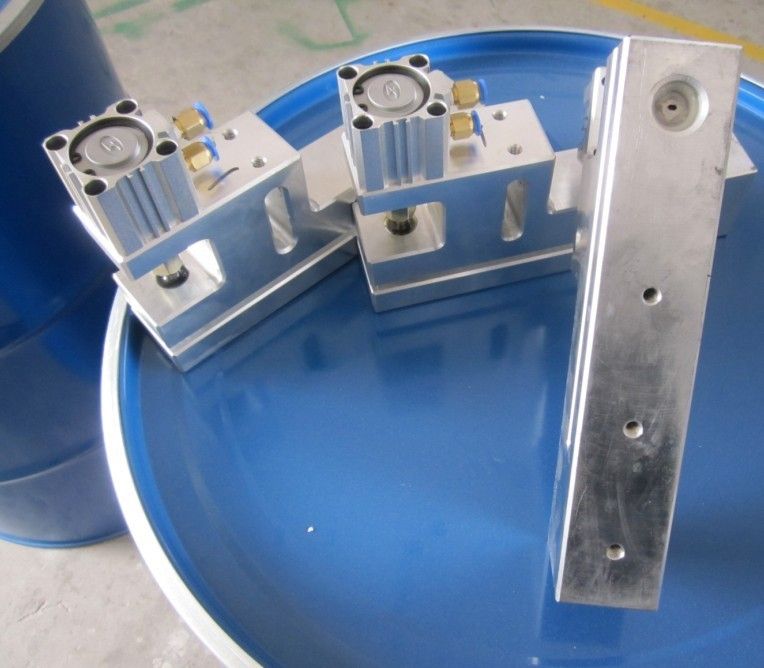

Discover the ravishing Pneumatic V Notch Punch Machine, celebrated for its unbeatable precision and robust design, engineered for notching plastic, uPVC, and aluminum profiles. Personalise your order with customizable die shapes and sizes. Featuring two-hand safety operation, a replaceable precision-cut blade, advanced pneumatic automation, and rapid cycle times under five seconds. Each unit ships fully assembled or CKD, as requested. Scarce in supply, with replacement parts readily availableorder today! This powerhouse offers low maintenance, high safety standards, and accommodates operators of semi-skilled level, making it ideal for diverse industrial environments.

Comprehensive Application Versatility

The Pneumatic V Notch Punch Machine excels in notching V-cuts on surfaces such as plastic profiles, uPVC, and aluminum, adapting seamlessly to varying widths between 10 and 100 mm. Its heavy-duty steel frame and advanced blade system make it suitable for plant installations on production floors. With a powder-coated or painted finish, the machine operates efficiently under diverse ambient conditions, perfect for high-volume environments and manufacturing plants requiring reliable notching with 0.2 mm accuracy.

Certifications, Sample Policy, and Supply Details

Arriving with CE Marking available upon demand, every punch machine is rigorously checked for compliance. Sample policy ensures customers can request trial units before making substantial commitments. Freight arrangements are flexible, with fully assembled or CKD shipped units delivered promptly. Supply ability supports large and small orders, making the pneumatic model ideal for bulk or distributed applications, ensuring consistent availability and timely arrival for global distributors and manufacturers.

Comprehensive Application Versatility

The Pneumatic V Notch Punch Machine excels in notching V-cuts on surfaces such as plastic profiles, uPVC, and aluminum, adapting seamlessly to varying widths between 10 and 100 mm. Its heavy-duty steel frame and advanced blade system make it suitable for plant installations on production floors. With a powder-coated or painted finish, the machine operates efficiently under diverse ambient conditions, perfect for high-volume environments and manufacturing plants requiring reliable notching with 0.2 mm accuracy.

Certifications, Sample Policy, and Supply Details

Arriving with CE Marking available upon demand, every punch machine is rigorously checked for compliance. Sample policy ensures customers can request trial units before making substantial commitments. Freight arrangements are flexible, with fully assembled or CKD shipped units delivered promptly. Supply ability supports large and small orders, making the pneumatic model ideal for bulk or distributed applications, ensuring consistent availability and timely arrival for global distributors and manufacturers.

FAQs of Pneumatic V Notch Punch Machine:

Q: How does the two-hand safety operation feature enhance user safety during machine operation?

A: The two-hand safety operation requires both hands to be used simultaneously, preventing accidental engagement and ensuring the operator remains safe while notching profiles.Q: What materials and profile widths can the Pneumatic V Notch Punch Machine process?

A: This machine is suitable for notching plastic, uPVC, and aluminum profiles with applicable widths ranging from 10 to 100 mm.Q: Where can the machine be installed, and what are the installation requirements?

A: The unit is ideal for plant manufacturing floors and production facilities, needing only a standard compressed air line for installation and operation.Q: When should maintenance such as blade sharpening and lubrication be performed?

A: Periodic blade sharpening and lubrication are recommended based on usage intensity, with regular checks ensuring optimal performance and machine longevity.Q: What is the process for ordering customizable dies and replacement parts?

A: Customers can request specific die shapes or sizes during their order placement. Replacement parts are always available, ensuring minimal downtime and continuous operation.Q: How does the pneumatic drive contribute to the machines efficiency?

A: The pneumatic drive system enables fast cycle times, with each notching operation completed in less than five seconds, increasing production output and reducing manual effort.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

ZS ENTERPRISE CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |