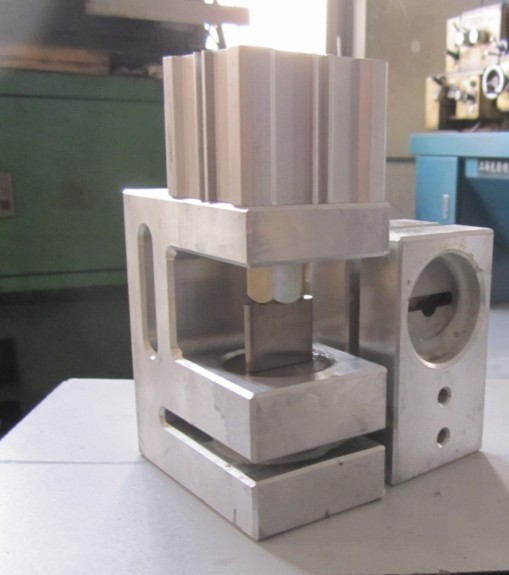

Double Holes Butterfly Punch for plastic bag

350.00 - 750.00 USD ($)/Piece

Product Details:

- Frequency 50 Hz

- Motor Power 0.37 kW (if applicable)

- Voltage 220V / 50Hz (electric type)

- Control System Manual Lever / Switch (if electric)

- Operating Temperature 5C to 45C

- Drive Manual/Servo (depending on version)

- Features High Durability, Ergonomic Handle, Sturdy Construction, Easy to Operate

- Click to View more

X

Double Holes Butterfly Punch for plastic bag Price And Quantity

- 1 Piece

- 350.00 - 750.00 USD ($)/Piece

Double Holes Butterfly Punch for plastic bag Product Specifications

- 1 kW (if electric)

- Approx 380 mm x 160 mm x 250 mm

- Silver with Black Handle

- Creating hanging holes in plastic bags, packaging, retail, supermarket use

- 0.37 kW (if applicable)

- 50 Hz

- Manual / Electric

- Manual Lubrication

- Low (<70 dB)

- Double Holes Butterfly Punch for Plastic Bag

- Manual / Pneumatic (as per variant)

- Manual Lever / Switch (if electric)

- Manual/Servo (depending on version)

- 5C to 45C

- High Durability, Ergonomic Handle, Sturdy Construction, Easy to Operate

- 220V / 50Hz (electric type)

- Up to 1 kW (electric version)

- 0.5 mm

- Not Applicable (manual)

- Mechanical Punching

- Metal Frame

- LDPE/HDPE/PP

- Butterfly Hole Punch

- Polished Metal

- Around 6-10 kg

- BHP-02

- Air Cooled (if electric)

- Hand Operated / Semi-Automatic

- Up to 5000 bags/hour

Double Holes Butterfly Punch for plastic bag Trade Information

- 1000 Piece Per Month

- 7 Days

- Middle East, Africa, Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe

Product Description

This smart and sophisticated Double Butterfly Punches helps in punching hanger holes on different kinds of plastic bags and paper products. The USP of these punches is its double design to create two holes at the same time thereby reduced time in punching is achieved. Arrays of requirement from customers are kept in mind in the designing process to make a successful and satisfying product at the end. Besides this, we lend guaranteed and outstanding quality to Double Butterfly Punches for long time use of them.

Efficient Hole Punching for Retail Packaging

Perfect for supermarkets, retail stores, and packaging industries, the Double Holes Butterfly Punch provides fast, clean holes for hanging displays. Its high capacity and manual or semi-automatic operation help streamline packaging processes and enhance product presentation.

Flexible and User-Friendly Operation

With manual and electric variants, this punch accommodates diverse operational needs. The adjustable guide ensures precise alignment, while ergonomic design and polished metal construction promote safe, easy handling and longevity.

Superior Durability and Versatility

From hardened tool steel blades to sturdy frame construction, this punch is built to last. Compatible with many plastic materials and supporting easy die-set changes, its a reliable solution for varying bag formats and applications.

FAQs of Double Holes Butterfly Punch for plastic bag:

Q: How do I align bags accurately for punching with this machine?

A: The machine includes an adjustable guide that allows you to perfectly position each bag, ensuring consistent hole placement every time and reducing waste from misaligned punches.Q: What types of bags and materials can this butterfly punch handle?

A: This model is compatible with LDPE, HDPE, PP, BOPP, and laminated plastic bags, making it suitable for a wide range of packaging needs in retail and export applications.Q: When should I replace the die set or blades on the punch?

A: Replace the die set or blades if you observe a decline in punching sharpness, uneven holes, or after prolonged heavy use. The punch is designed for easy die replacement to minimize downtime.Q: Where can this machine be installed or used?

A: Its tabletop mount and portable design allow it to be used at packaging stations, retail backrooms, manufacturing floors, or workshops, offering flexibility in various work environments.Q: What is the standard operating process for using the punch?

A: To operate, align the bag using the adjustable guide, engage the manual lever or switch (if electric), and proceed to punch. For semi-automatic variants, minimal manual input is required. The process ensures 0.5 mm accuracy with low noise levels.Q: How does this butterfly punch benefit packaging operations?

A: By enabling rapid and precise hole punchingup to 5,000 bags per hourit streamlines production, enhances product display options, and supports multiple formats, reducing operational time and increasing efficiency.Q: Is this machine easy to maintain and what care is required?

A: Yes, it features a low-maintenance design. Regular manual lubrication and occasional cleaning are sufficient to ensure optimal, long-lasting performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hole Punching Machine' category

|

ZS ENTERPRISE CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |