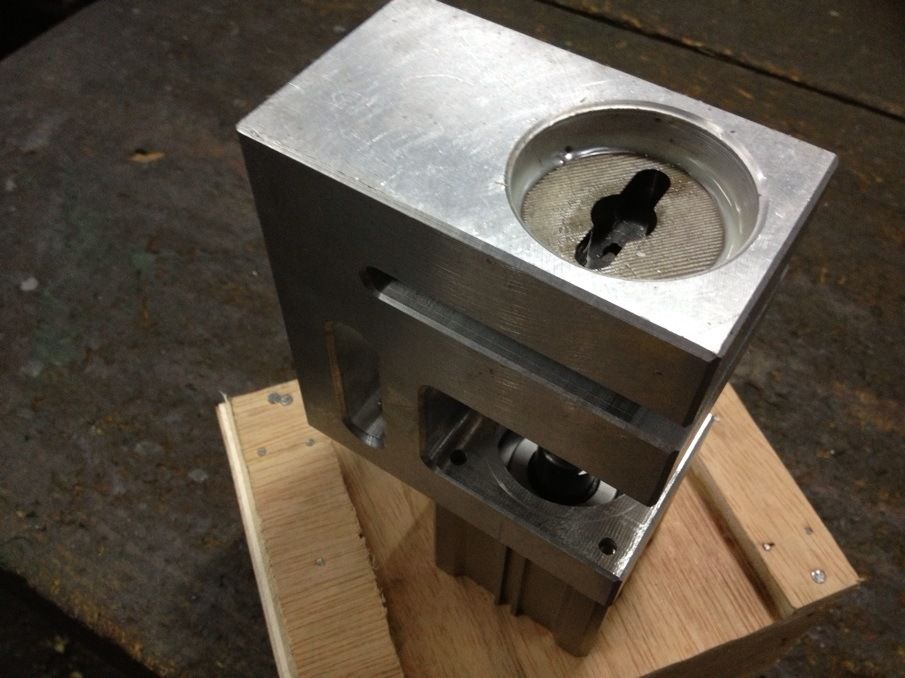

Hanger Hole Puncher/Hanger puncher for plastic film

350 USD ($)/Piece

Product Details:

- Machine Type Manual Puncher

- Model No HH-01M

- Frame Type Metal body

- Control System Manual

- Operating Temperature Ambient

- Features Easy to use, portable, durable, ergonomic handle

- Plastic Processed PE, PP, OPP, PVC, LDPE plastic films

- Click to View more

X

Hanger Hole Puncher/Hanger puncher for plastic film Price And Quantity

- 350 USD ($)/Piece

- 200.00 - 500.00 USD ($)/Piece

- 1 Piece

Hanger Hole Puncher/Hanger puncher for plastic film Product Specifications

- Metal body

- Punching hanger holes in plastic films, bags, packaging

- Manual

- Manual, hand-operated

- 220mm x 65mm x 35mm

- Mechanical Punching

- Minimal (manual operation)

- Manual

- 0.75

- HH-01M

- Up to 3,000-5,000 holes per day

- Silver / Metallic

- High hole placement accuracy

- Hand Operated

- Polished Metal

- Hanger Hole Puncher

- Manual Puncher

- Easy to use, portable, durable, ergonomic handle

- Ambient

- Manual

- PE, PP, OPP, PVC, LDPE plastic films

Hanger Hole Puncher/Hanger puncher for plastic film Trade Information

- 1000 Piece Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

This Hanger Hole Puncher is precisely manufactured with the use of excellent quality raw materials and the contemporary techniques in tune with the international quality standards. Widely acknowledged in the bags manufacturing industry for cutting holes of fixed sizes, the puncher provided by us is known for its outstanding features. Our quality experts check this puncher on various parameters of quality in order to ensure its flawlessness. Further, we offer this Hanger Hole Puncher at most economic rates to the clients.

Features:

Features:

- Easy installation

- High strength

- Long service life

- Precisely designed

Efficient Euro Slot Punching for Retail Packaging

The HH-01M offers a straightforward solution for retail and display packaging by providing speedy and accurate Euro slot holes in plastic films. It handles materials like PE, PP, OPP, PVC, and LDPE up to 250 microns, making it highly versatile for various industries including garment and product display.

User-Friendly and Safe Operation

Engineered for safety and comfort, the puncher features an ergonomic, cushioned grip and an integrated finger guard. The compact design and minimal weight (only 0.75 kg) allow for easy use, transport, and storage, making it ideal for workplaces with limited space or for on-the-go needs.

Minimal Maintenance and High Durability

Built with a polished metal body and hardened steel blade, the HH-01M requires very little maintenance. Replacement blades and parts are available upon request, ensuring long-term utility with consistent, high-precision results with every use.

FAQs of Hanger Hole Puncher/Hanger puncher for plastic film:

Q: How do I operate the HH-01M Hanger Hole Puncher?

A: To use the HH-01M, simply position the plastic film under the blade, grip the ergonomic handle, and apply manual pressure. The mechanical system will punch a clean Euro slot (32mm x 9mm), providing high placement accuracy without needing any power supply or special expertise.Q: What types of plastic films are compatible with this hole puncher?

A: The HH-01M is designed for use with a range of plastic films, including PE, PP, OPP, PVC, and LDPE, with a maximum thickness of 250 microns. This flexibility covers most packaging and display material requirements.Q: When should I consider replacing the blade or any parts?

A: The hardened steel blade is durable and maintains its sharpness over extensive use. However, if you notice decreased cutting efficiency or irregular holes, contact the supplier for replacement parts, which are readily available on request.Q: Where can this hanger puncher be used?

A: It is ideal for use in retail, packaging environments, product display preparation, and garment bag manufacturinganywhere precise Euro slot holes are needed in plastic films. Its portability and manual operation make it suitable for both factory and on-site applications.Q: What are the main benefits of using the HH-01M puncher?

A: Key benefits include high hole placement accuracy, ease of use, minimal noise, portability, and a safe ergonomic design. Additionally, its high production capacity (up to 5,000 holes a day) makes it an efficient choice for small to medium-scale operations.Q: How do I maintain the puncher for optimal performance?

A: Routine maintenance is minimal. Regularly clean the blade and surrounding area to remove debris and check for wear on moving parts. Lubricate lightly if necessary, and store in a dry environment to maintain its polished metal finish.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hole Punching Machine' category

|

ZS ENTERPRISE CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |