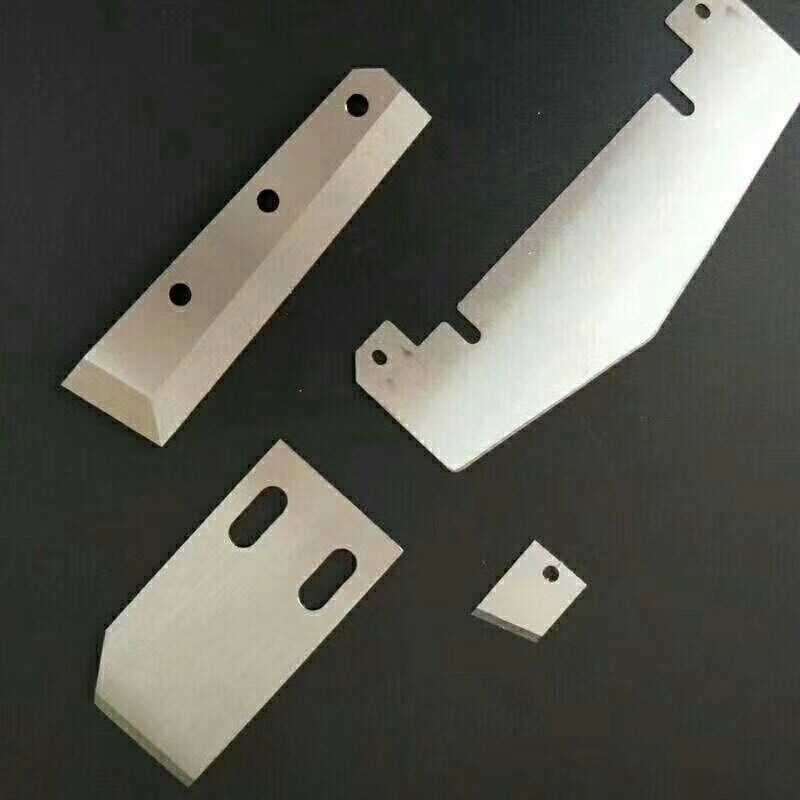

Perforating Blade

40 USD ($)/Piece

Product Details:

- Precision High Precision Engineered

- Surface Treatment Polished

- Shape Rectangular with Perforated Edge

- Design Special Perforated Design

- Type Perforating Blade

- Blade Material High Carbon Steel

- Handle Material No Handle (Industrial Mounting)

- Click to View more

X

Perforating Blade Price And Quantity

- 10 Piece

- 40 USD ($)/Piece

Perforating Blade Product Specifications

- High Precision Engineered

- 60-62 HRC

- Very Sharp

- 2.5 mm

- High Carbon Steel

- Polished

- Rectangular with Perforated Edge

- Perforating Blade

- No Handle (Industrial Mounting)

- Micro Tooth for Fine Perforation

- Special Perforated Design

- Mirror Finish

- Paper Cutting, Film, Foil, and Packaging Industry

Perforating Blade Trade Information

- 1000 Piece Per Month

- 7 Days

- Yes

- Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Australia

Product Description

The offered Perforating Blade is widely used for cutting paper. It is also always high on demand due to its robust design, smooth edges, fine finishing, and high strength. Moreover, it can be availed from us in required sizes and shapes. It usually consists of a hole in the center and high-quality blades on the outer surface. Further, this Perforating Blade can be adopted for precisely cutting materials, as it has accurate dimensions. We also perform certain quality tests on it to make sure that it will last longer and will deliver optimum performance.

Exceptional Cutting Precision

This perforating blade features high-precision engineering that allows for clean, consistent cuts on a variety of materials, including paper, film, and foil. Its micro-serrated teeth deliver finely detailed perforations, essential for packaging and converting operations requiring accuracy and uniformity.

Built for Industrial Performance

Manufactured from robust high carbon steel and treated for corrosion resistance, the blade endures harsh industrial settings. With a hardness rating of 60-62 HRC and temperature resistance up to 250C, it guarantees extended operational life, reducing the need for frequent replacements.

Customization to Suit Your Needs

Flexibility is at the core of this blades design. Users can request customizations for both blade dimensions and tooth patterns, making it well-suited for specialized applications across various industries. Its universally compatible slot/fit mounting streamlines installation processes.

FAQs of Perforating Blade:

Q: How is the perforating blade installed in industrial perforating machines?

A: The blade is designed with a slot/fit mounting style, allowing easy integration into most universal perforating machines. Simply align the blade with the designated slots or mounting area and secure it as per the machines specifications.Q: What materials can this micro-serrated blade efficiently perforate?

A: This blade is engineered for use with paper, film, foil, and similar packaging materials, delivering fine and precise perforations due to its specialized micro tooth edge.Q: When should I consider customizing the blades size or tooth pattern?

A: Customization is recommended when your application requires specific perforation characteristics or when your machinery demands non-standard dimensions. This ensures optimal fit and performance for specialized production needs.Q: Where is this perforating blade primarily used?

A: Primarily, it is utilized in the paper cutting, film converting, foil processing, and packaging industries, within both automated and manual perforating machine setups.Q: What is the process for maintaining the blade to ensure durability and sharpness?

A: Routine cleaning after use and regular inspection for wear will help maintain the blades sharpness and prolong its lifespan. Its corrosion-resistant, mirror-polished finish also simplifies maintenance.Q: How does the blades design benefit industrial applications?

A: The special perforated design and micro-serrated edge enable uniform, precise perforations with minimal material disruption, which is ideal for high-volume industrial processing and packaging tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Knives' category

|

ZS ENTERPRISE CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |