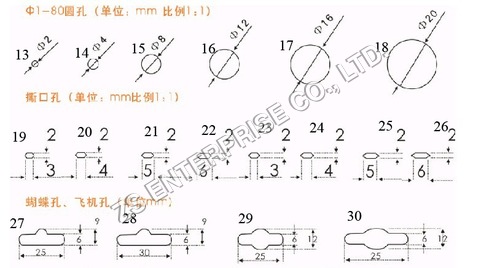

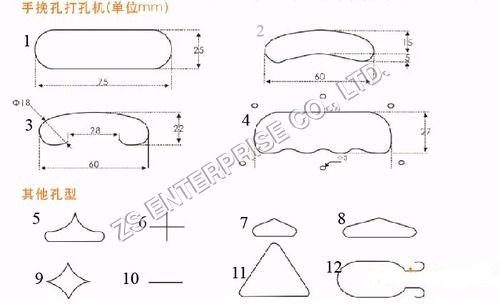

Hole Shapes

100.00 - 200.00 USD ($)/Piece

Product Details:

- Working Process CNC milling, EDM, Grinding, Drilling

- Core Material Hardened Tool Steel / High-grade Alloy

- Mould Base P20 Steel / Standard Hardened Base

- Life Span Up to 1,000,000 shots (depends on usage and material)

- Tolerance 0.01 mm

- Material Alloy Steel / Tool Steel / Carbide Inserts

- Shaping Mode Multiple Hole Shapes (Square, Round, Oblong, Hexagon, Rectangle, Custom)

- Click to View more

X

Hole Shapes Price And Quantity

- 100.00 - 200.00 USD ($)/Piece

- 1 Piece

Hole Shapes Product Specifications

- Profiled Punches for Multiple Hole Forms

- Multiple Hole Shapes (Square, Round, Oblong, Hexagon, Rectangle, Custom)

- Hardened Tool Steel / High-grade Alloy

- CNC milling, EDM, Grinding, Drilling

- 0.01 mm

- P20 Steel / Standard Hardened Base

- Up to 1,000,000 shots (depends on usage and material)

- Alloy Steel / Tool Steel / Carbide Inserts

- Custom Die Head for Various Shapes

Hole Shapes Trade Information

- 1000 Piece Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

Jump on the chance to experience resplendent precision and noteworthy performance with our affordable Hole Shapes. Order today and discover ravishing results in sheet metal punching and diverse precision components for automotive and electronics applications. Featuring mirror polish or customized surface finishes, high-volume multi-cavity support, and integrated water cooling channels, these molds guarantee consistent geometry and easy mould maintenance. Our products, crafted from hardened alloy steels with vacuum quenching, are customizable in size and shape, offering superior tolerance and a lifespan of up to 1,000,000 shots. Secure your excellenceorder now from Chinas leading distributor and supplier!

Hole Shapes: Usage & Applications

Our Hole Shapes are ideal for sheet metal punching, precision components, automotive, and electronics. With multi-cavity support, users benefit from enhanced productivity for both high-volume and specialized manufacturing. Crafted from alloy steel, tool steel, or carbide inserts, the shapes include square, round, oblong, hexagon, rectangle, and custom forms. Designed for critical applications, these moulds enable consistently accurate profiles, ensuring reliability for mass production and intricate engineering tasks.

Hole Shapes: Export Markets & Supply

Estimate your demand confidentlyour high-capacity supply ensures timely delivery and competitive sale prices for every order. We meet bulk requirements through rapid production and reliable distribution channels, supporting main export markets across Asia, North America, and Europe. With direct FOB sales from Chinas leading ports, we guarantee smooth international shipping, enabling manufacturers everywhere to benefit from consistent quality and robust availability. Secure your supply now for high-volume or specialist needs.

Hole Shapes: Usage & Applications

Our Hole Shapes are ideal for sheet metal punching, precision components, automotive, and electronics. With multi-cavity support, users benefit from enhanced productivity for both high-volume and specialized manufacturing. Crafted from alloy steel, tool steel, or carbide inserts, the shapes include square, round, oblong, hexagon, rectangle, and custom forms. Designed for critical applications, these moulds enable consistently accurate profiles, ensuring reliability for mass production and intricate engineering tasks.

Hole Shapes: Export Markets & Supply

Estimate your demand confidentlyour high-capacity supply ensures timely delivery and competitive sale prices for every order. We meet bulk requirements through rapid production and reliable distribution channels, supporting main export markets across Asia, North America, and Europe. With direct FOB sales from Chinas leading ports, we guarantee smooth international shipping, enabling manufacturers everywhere to benefit from consistent quality and robust availability. Secure your supply now for high-volume or specialist needs.

FAQs of Hole Shapes:

Q: How do integrated water cooling channels enhance the performance of Hole Shapes?

A: Integrated water cooling channels facilitate efficient heat dissipation, reducing thermal deformation during the punching process and helping maintain the resplendent consistency of hole geometry in high-volume production environments.Q: What applications are Hole Shapes most suitable for?

A: Hole Shapes are primarily used in sheet metal punching, precision components, automotive, and electronics industries, thanks to their customizable designs and exceptional durability.Q: Where can Hole Shapes be supplied from and exported to?

A: Hole Shapes are supplied directly from China, serving prominent export markets such as Asia, North America, and Europe through well-established distribution and trading channels.Q: When should custom hole shapes be ordered for specific requirements?

A: Custom hole shapes should be ordered when projects demand specialized profiles, unique dimensions, or precise fitments, ensuring the final product matches exact engineering and manufacturing specifications.Q: What is the process for maintaining and cleaning the moulds?

A: The moulds feature an easy dismantling design for quick cleaning, helping ensure smooth operation, longevity, and reduction in production downtime.Q: How does the heat treatment process benefit the hole shape moulds?

A: Vacuum quenching and tempering enhance core strength, surface hardness, and overall life span, ensuring up to 1,000,000 shots while maintaining critical tolerances and product reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hole Shape For Reference' category

|

ZS ENTERPRISE CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |