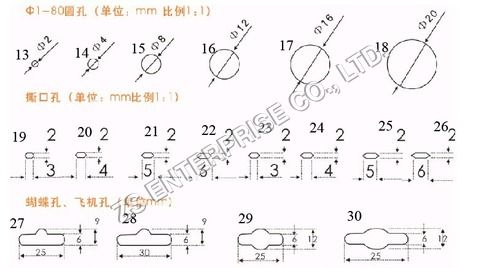

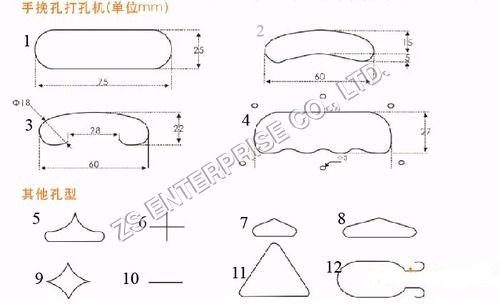

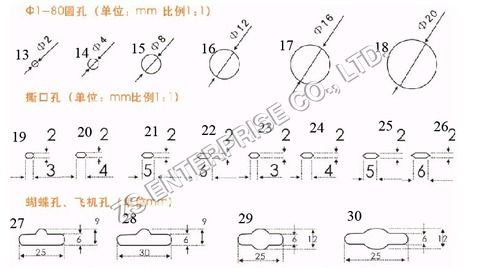

Hole Shapes 3

100.00 - 200.00 USD ($)/Piece

Product Details:

- Working Process CNC Machining, EDM, Grinding

- Core Material Alloy Steel

- Tolerance 0.01 mm

- Mould Base High-Grade Steel

- Life Span Up to 500,000 Shots

- Material Tool Steel, Carbide Option Available

- Shaping Mode Compression Mould

- Click to View more

X

Hole Shapes 3 Price And Quantity

- 100.00 - 200.00 USD ($)/Piece

- 1 Piece

Hole Shapes 3 Product Specifications

- High-Grade Steel

- Alloy Steel

- 0.01 mm

- Tool Steel, Carbide Option Available

- Precision Hardened Steel

- Hardened Tool Steel

- Up to 500,000 Shots

- CNC Machining, EDM, Grinding

- Compression Mould

Hole Shapes 3 Trade Information

- 1000 Piece Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

Buy Online the popular Hole Shapes 3 Punch Dies, featuring a radiant mirror polish finish for splendiferous durability and precision. Unlock preeminent adaptability with multi-cavity custom shapes: round, oval, square, or designs made as per your requirements. Engineered for industrial hole punching and shaping, each unit is vacuum heat-treated to attain a hardness of HRC 52-58, offering a life span of up to 500,000 shots. Manufactured in China using high-grade alloy tool steel with CNC machining and EDM processes. DIN/ISO compatible, with fast lead times of 1530 days and flexible customization options. Distributor, exporter, manufacturer, supplier, and trader services available.

Site of Application & Special Features

Hole Shapes 3 is designed for industrial environments needing efficient hole punching and shaping. Its highly effective in manufacturing, automotive, electronics, and metal fabrication sectors. Special features include support for multi-cavity demands, mirror-polished surfaces for reduced friction, precision tolerance of 0.01 mm, and custom shapes according to client drawings. The advanced vacuum heat treatment and use of DIN/ISO standard components ensure longevity and superior performance during intensive operations.

Supply Ability & Certifications

Hole Shapes 3 units are charged and shipped with care, ensuring reliable handover to clients in various markets. The supply ability is robust and covers repeated, high-volume orders thanks to efficient production processes and certification for quality assurance. Our main domestic market spans China and key industrial regions, supported by international export capabilities. Each product is certified to industry standards for safety and precision, so clients receive only premium, pre-certified solutions on delivery.

Site of Application & Special Features

Hole Shapes 3 is designed for industrial environments needing efficient hole punching and shaping. Its highly effective in manufacturing, automotive, electronics, and metal fabrication sectors. Special features include support for multi-cavity demands, mirror-polished surfaces for reduced friction, precision tolerance of 0.01 mm, and custom shapes according to client drawings. The advanced vacuum heat treatment and use of DIN/ISO standard components ensure longevity and superior performance during intensive operations.

Supply Ability & Certifications

Hole Shapes 3 units are charged and shipped with care, ensuring reliable handover to clients in various markets. The supply ability is robust and covers repeated, high-volume orders thanks to efficient production processes and certification for quality assurance. Our main domestic market spans China and key industrial regions, supported by international export capabilities. Each product is certified to industry standards for safety and precision, so clients receive only premium, pre-certified solutions on delivery.

FAQs of Hole Shapes 3:

Q: How is the customization process for Hole Shapes 3 handled?

A: Clients can submit detailed drawings or specifications, and our expert team will customize the shape, cavity number, and sizes according to requirements. We support unique designs and guarantee precision with advanced CNC machining and EDM processes.Q: What application areas benefit most from Hole Shapes 3?

A: Hole Shapes 3 is especially beneficial in industries requiring high-volume hole punching and shaping, such as automotive, electronics manufacturing, and metal fabrication, where consistency, durability, and precision are essential.Q: When can I expect my Hole Shapes 3 order to be shipped?

A: Production lead time is typically 1530 days, depending on customization and order volume. Orders are shipped promptly upon completion and quality verification.Q: Where are Hole Shapes 3 components manufactured and supplied?

A: Hole Shapes 3 is manufactured in China with supply capabilities covering domestic markets and international export destinations. We act as distributor, exporter, manufacturer, supplier, and trader to ensure global availability.Q: What are the main benefits of vacuum heat treatment and mirror polish in Hole Shapes 3?

A: Vacuum heat treatment enhances surface hardness and longevity, while the mirror polish finish reduces friction, prevents wear, and ensures precise shaping even under continuous heavy-duty industrial usage.Q: How do I ensure compatibility with existing systems?

A: Hole Shapes 3 is designed with DIN/ISO standard components, making it easily compatible with most industrial mould bases and punch systems for seamless integration into your existing processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hole Shape For Reference' category

|

ZS ENTERPRISE CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |