Industrial Knife

25 USD ($)/Piece

Product Details:

- Surface Treatment Polished

- Design Industrial Standard

- Precision High Precision

- Shape Rectangular

- Type Industrial Knife

- Blade Material High Speed Steel (HSS)

- Handle Material Metal

- Click to View more

X

Industrial Knife Price And Quantity

- 25 USD ($)/Piece

- 10 Piece

Industrial Knife Product Specifications

- 6 mm (approx.)

- Rectangular

- Smooth

- Industrial Knife

- 58-60 HRC

- Razor Sharp

- Metal

- Single Side or Both Side Available

- High Precision

- Polished

- Cutting, Trimming, Industrial Processing

- High Speed Steel (HSS)

- Industrial Standard

Industrial Knife Trade Information

- 1000 Piece Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

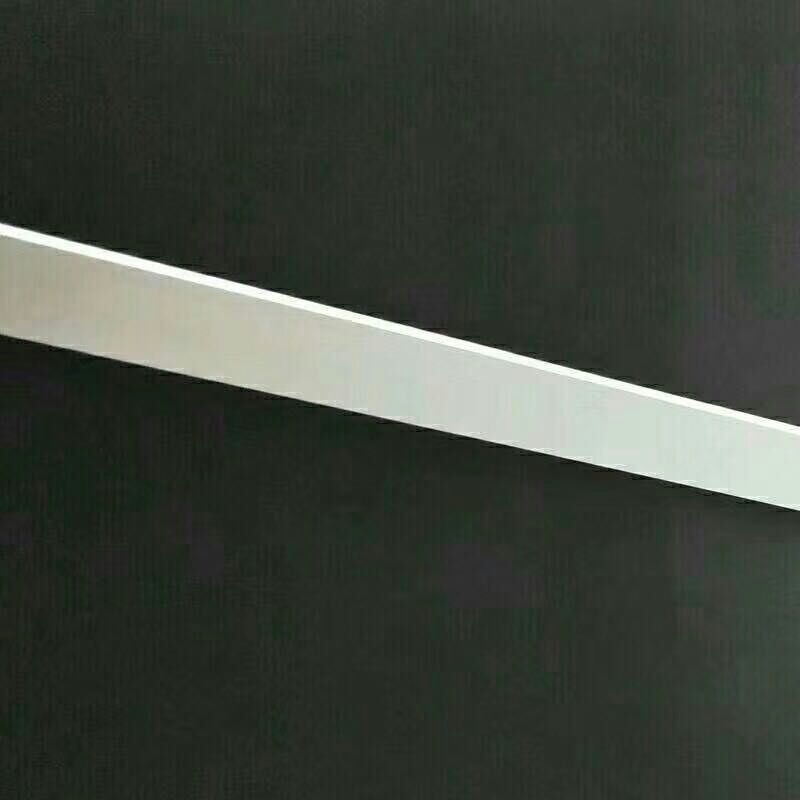

Industrial Knife is specifically designed for cutting materials with precision in a certain manner. Thus, only hard metals are used to ensure that they can offer sharp edges for cutting different types of materials. In addition, it is an easy to use tool that provides high performance with accurate results. Thus, it is highly utilized in industries for obtaining precisely cut workpieces. Industrial Knife also receives high appreciation for its corrosion resistant surface and low maintenance feature. Moreover, it can be availed from us in required specifications, as per individuals needs.

Exceptional Durability and Precision

Crafted from high speed steel and polished to a smooth, corrosion-resistant finish, this industrial knife guarantees lasting sharpness and dependable performance. With a hardness of 58-60 HRC and high-precision edge, it is tailored for demanding industrial applications and rigorous operating environments.

Versatile Application Across Industries

Suitable for use in paper, plastic, wood, and metal processing, this blade adapts seamlessly to multiple machine types and tasks. Its robust design and customizable features make it an ideal choice for diverse cutting and trimming requirements in both automatic and manual systems.

Customizable to Meet Your Needs

With variable mounting options, cutting angles, and edge trimming choices, this knife is engineered to fit specific machinery and process requirements. Its rectangular, industrial-standard design ensures easy integration into various cutting setups, providing both efficiency and flexibility.

FAQs of Industrial Knife:

Q: How is this industrial knife installed on machines?

A: The knife is designed with bolt holes in specified locations, allowing for straightforward and secure mounting on both automatic and manual machines. This facilitates quick integration and replacement as needed across different equipment.Q: What industries can benefit from using this industrial knife?

A: This knife is well-suited for paper, plastic, wood, and metal processing industries, making it valuable for businesses engaged in cutting, trimming, and shaping various materials within these sectors.Q: When should I consider replacing the knife blade?

A: Replacement timing depends on usage intensity, but you should change the blade when you notice diminished cutting performance or increased resistance during operation, despite the knifes high precision and sharpness.Q: Where can this knife be sourced from?

A: As a distributor, exporter, manufacturer, supplier, and trader in China, the product is widely available for bulk orders and export globally, ensuring dependable supply for industrial needs.Q: What is the process for customizing the cutting angle or edge style?

A: Custom cutting angles and edge styles can be specified during ordering, allowing you to tailor the knifes performance to your exact application requirements for optimum results.Q: How does the knifes corrosion resistance benefit users?

A: Thanks to its corrosion-resistant high speed steel construction and polished surface, the knife maintains sharpness and functionality over time, reducing maintenance needs and operational downtime.Q: What advantages does the high precision and razor sharpness of the blade offer?

A: The excellent precision and razor-sharp edge ensure clean, accurate cuts, minimizing material waste and increasing efficiency in industrial processing tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Knives' category

|

ZS ENTERPRISE CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |